Precision UV-C processing for complex

liquids

Biology

Chemistry

Physics

FloUV applies advanced UV-C science and fluid-dynamics engineering to deliver uniform microbial inactivation in opaque and viscous liquids—without heat, pressure, or chemical compromise.

The result is precise safety control while preserving native proteins, bioactives, and functional quality.

Biology

FloUV uses non-thermal UV-C light to inactivate microorganisms at the molecular level by directly targeting their DNA and RNA. When microbes are exposed to UV-C wavelengths, the energy induces the formation of thymine and pyrimidine dimers in genetic material, disrupting replication and transcription pathways essential for cell survival.

By preventing microorganisms from reproducing and repairing themselves, FloUV renders bacteria, yeasts, molds, and viruses non-viable—achieving microbial safety without heat or chemicals. This DNA-level disinfection mechanism allows milk and other complex liquids to be safely processed while preserving native proteins, bioactives, and functional quality that are otherwise degraded during thermal treatment.

Chemistry

FloUV preserves food chemistry by achieving microbial safety without thermal stress, which is the primary driver of nutrient and bioactive loss in conventional processing. By avoiding high temperatures, FloUV minimizes protein denaturation and aggregation (protecting native functionality), reduces heat-accelerated oxidation pathways that can degrade sensitive bioactives, and limits unwanted reactions such as Maillard browning that can alter flavor and nutritional quality. Because the process is non-thermal and tightly controlled, the liquid’s key compositional attributes—native proteins, bioactive fractions, and heat-sensitive quality markers—remain substantially closer to their

Physics

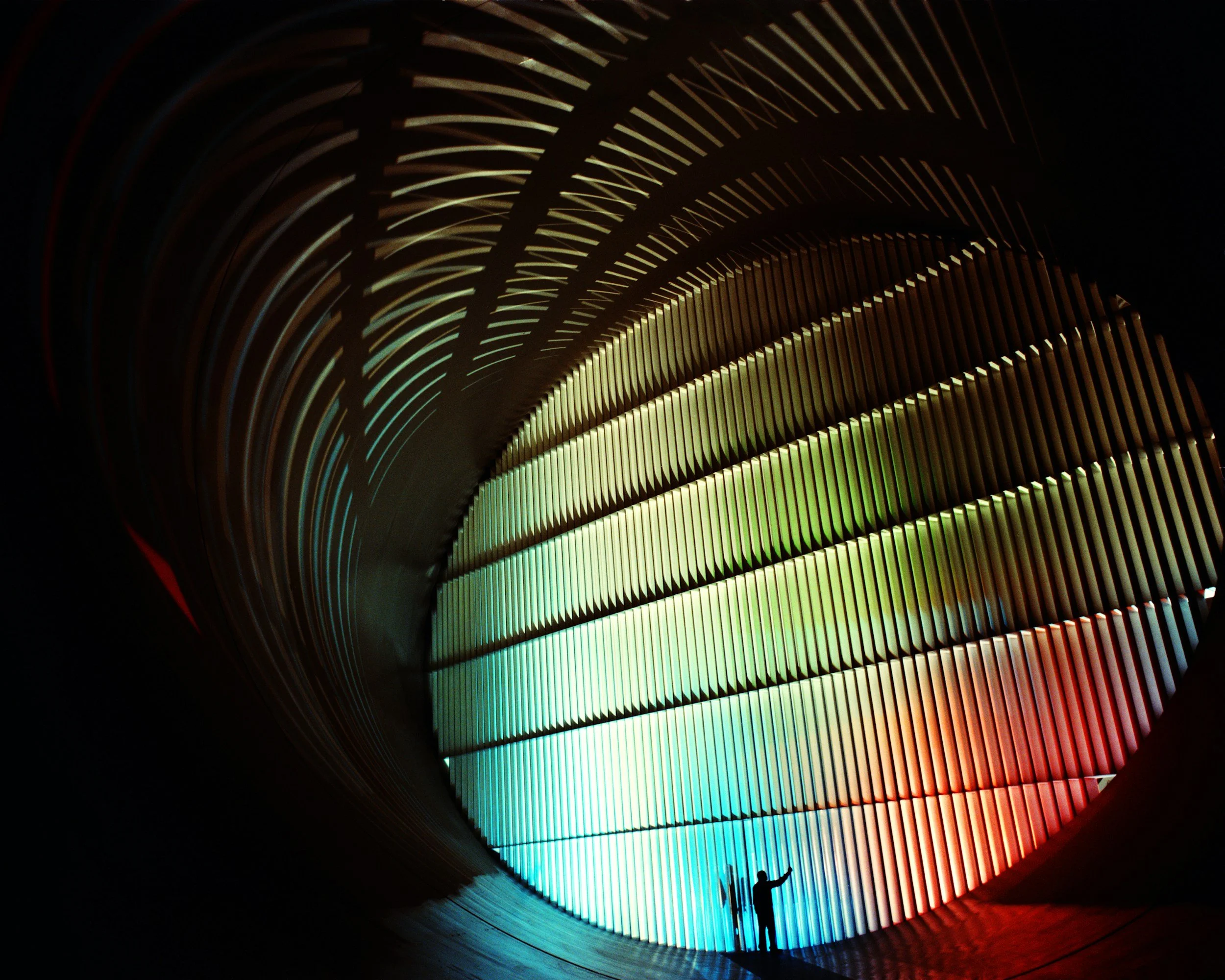

FloUV applies advanced hydrodynamic engineering to control how liquids move, mix, and interact with UV-C light inside the reactor. At the core of the platform is a patented serpentine flow-path design, engineered to create controlled turbulence and continuous radial mixing in opaque and viscous liquids. This flow behavior ensures that all fluid elements are repeatedly brought into the UV-C exposure zone, eliminating channeling and stagnant regions common in conventional UV systems.

By precisely controlling residence time, flow velocity, and exposure geometry, FloUV delivers a uniform and quantifiable UV-C dose across the entire liquid volume. This physics-driven reactor design enables repeatable, validated microbial inactivation while avoiding overexposure—allowing safety targets to be met without heat, pressure, or chemical intervention, and while preserving sensitive product attributes.

A controlled pathway for microbial inactivation

What it is really ?

FloUV is built around a simple but powerful idea , microbial safety is achieved not by forcing liquids through heat or pressure, but by guiding every part of the liquid through a precisely controlled UV-C exposure pathway.

In conventional systems, liquids tend to follow the path of least resistance—leaving portions under-treated. FloUV overcomes this by using a patented serpentine flow architecture that continuously redistributes the liquid, ensuring that microorganisms are repeatedly and uniformly exposed to germicidal UV-C light.

As microbes travel through this engineered pathway, UV-C light disrupts their DNA and RNA, preventing replication and rendering them non-viable. The process is non-thermal, non-chemical, and repeatable—delivering microbial safety while preserving the native chemistry, bioactives, and functionality of the liquid.

This controlled exposure concept enables safe, energy-efficient processing across applications such as:

• Raw and specialty milk processing

• Bioactive ingredient streams (lactoferrin, IgA, whey fractions)

• Beverages, juices, and functional liquids

• Sugar syrups and process ingredients

FloUV doesn’t force liquids to change—it guides them safely through light.

UV-C, Re-Engineered for Opaque Liquids.

Conventional UV systems work in water because high UV transmittance allows photons to penetrate the entire fluid volume, making dose largely a function of lamp output and residence time. In opaque liquids, absorption and scattering collapse photon penetration to the boundary, leaving fluid cores under-treated and dose non-uniform. FloUV resolves this by reversing the logic: instead of forcing light into the liquid, it engineers helical flow and Dean vortex–driven circulation to repeatedly move every micro-volume to the illuminated surface, enabling uniform, validated UV-C dose delivery independent of optical opacity.

Controlled liquid pathway through UV-transparent tubing

How does it works?

The liquid enters the FloUV reactor and flows through UV-C–transmissive FEP tubing, selected for its high optical clarity at germicidal wavelengths, chemical inertness, and food-grade performance. The tubing defines a closed, hygienic pathway that maintains laminar-to-controlled transitional flow depending on application viscosity and throughput.

Engineered serpentine geometry for uniform exposure

The FEP tubing is wound around a structural support with a defined curvature and serpentine configuration. This geometry induces secondary flow and continuous radial mixing within the tube, preventing channeling and stagnant zones. As the liquid advances, fluid elements are repeatedly displaced toward the tubing wall and back into the bulk stream—ensuring that microorganisms do not bypass the treatment zone.

Precise UV-C dose delivery at the tubing wall

High-intensity UV-C lamps are strategically positioned around the tubing coil, with lamp spacing, orientation, and distance engineered to deliver a known irradiance profile at the inner wall of the FEP tubing. UV-C photons transmit through the tubing wall and penetrate the flowing liquid, exposing microorganisms to a controlled cumulative UV-C dose defined by flow rate, tubing length, and lamp output. This enables repeatable microbial inactivation without heat, pressure, or chemical intervention.

FloUV value Proposition.

Superior microbial disinfection

Delivers validated, non-thermal UV-C inactivation of vegetative cells, pathogens, yeast, molds, viruses, and heat-resistant spores. Also enables photochemical degradation of select mycotoxins, while meeting FDA HACCP expectations with 5–7 log pathogen reduction—without heat or chemicals.

Gental Preservation

Non-thermal UV-C processing preserves natural taste, nutrition, and functionality—no heat, no pressure, no chemicals. Protects heat-sensitive bioactives (vitamins, polyphenols, amino acids) while minimizing oxidative enzyme activity. Retains native flavor and aroma, enabling cold-process alternatives to thermal and HPP technologies.

High flow-through & energy efficient

Unlike batch-based High-Pressure Pasteurization (HPP), FloUV operates as a continuous, inline flow-through system, delivering throughput comparable to HTST without heat. The process achieves 100% yield with no rejection, since liquids are treated directly—no membranes, no hold tanks, no batching. With no moving parts, minimal maintenance, low downtime, and CIP cycles typically every 24 hours, FloUV offers a highly energy-efficient solution that is easily retrofitted into existing processing lines, making it ideal for large-scale operations requiring speed, precision, and operational simplicity.

FloUV Application

-

FloUV for Juices

FloUV delivers pasteurization-equivalent safety for juices—without heat. Engineered for opaque and turbid liquids, our non-thermal UV-C platform protects freshness, nutrition, and flavor while dramatically reducing energy and processing stress

-

FloUV for Dairy

FloUV is a next-generation, non-thermal UV-C milk treatment technology designed to deliver food-safety performance without compromising milk’s natural quality. Unlike heat pasteurization, FloUV precisely delivers UV-C energy through opaque milk to inactivate pathogens and spoilage organisms while preserving bioactive proteins, flavor, and nutritional integrity

-

FloUV for Plant Based Beverage

Flouv provides non-thermal UV-C pasteurization for plant-based beverages like oat, almond, and soy milk—ensuring pasteurization-equivalent safety while preserving fresh taste, light color, and nutrition, with up to 90% lower energy use than heat.

The FloUV technology blogs

If you’d like to dive deeper into how FloUV validates non-thermal UV-C performance, explore our latest technology and validation blog posts below.

Explore how FloUV validates UV-C performance in opaque liquids using dose-response modeling, biodosimetry, and Reduction Equivalent Fluence to deliver repeatable, auditable microbial safety.

Inside FloUV’s Scientific Validation Methodology

FloUV solves UV-C’s biggest challenge in opaque liquids. Learn how its unique flow design delivers uniform microbial lethality with lower energy and better quality retention.

Engineering UV-C for Opaque Liquids

Dr Ankit Patras

Chief Technology Office

Technology Contact

For any enquiries or questions regarding our technology and related projects, please contact our Deep Tech department or book a meeting.