Redefining Dairy Safety Without Heat

FloUV applies precision UV-C dosing engineered for optically dense milk, delivering validated ≥5-log pathogen reduction while retaining lactoferrin, IgA, enzymes, and fresh dairy flavor—without thermal damage.

The Dairy Processing Dilemma

-

Safety vs. Quality Trade-off

Thermal pasteurization reliably inactivates pathogens—but degrades heat-sensitive bioactives like lactoferrin, IgA, and enzymes critical to dairy nutrition and functionality.

-

Escalating Thermal Intensity

Heat-resistant organisms are pushing processors toward higher temperatures and longer hold times, amplifying flavor damage, oxidation, and nutrient loss.

-

Cost & Sustainability Pressure

Thermal systems demand high energy, water, and CIP loads, while non-thermal alternatives like HPP introduce batching, yield loss, and high CAPEX.

-

Limited Innovation Headroom

Most “alternatives” were adapted from water or juice processing—not engineered for optically dense milk—leaving processors stuck with legacy constraints.

“A new era in dairy safety and quality” FloUV’s precision UV-C technology unlocks non-thermal microbial control and quality preservation in milk and dairy streams. We call this SMART UV-C DAIRY PROCESSING: a combination of engineered flow dynamics and controlled fluence dosing that delivers consistent safety without compromising bioactives, flavor, or nutrition.

Superior dairy quality

FloUV’s UV-C platform is engineered specifically for optically dense milk systems, where absorption and scattering limit conventional UV performance. By combining controlled hydrodynamics with precision fluence delivery, FloUV achieves validated ≥5-log inactivation of milk pathogens while preserving heat-sensitive bioactives such as lactoferrin, IgA, lysozyme, and bile-salt-stimulated lipase. Unlike thermal pasteurization, FloUV maintains milk’s biochemical integrity, flavor profile, and functional quality—delivering microbial safety without structural or nutritional degradation.

Validation case study: microbial safety & Bioactive in milk

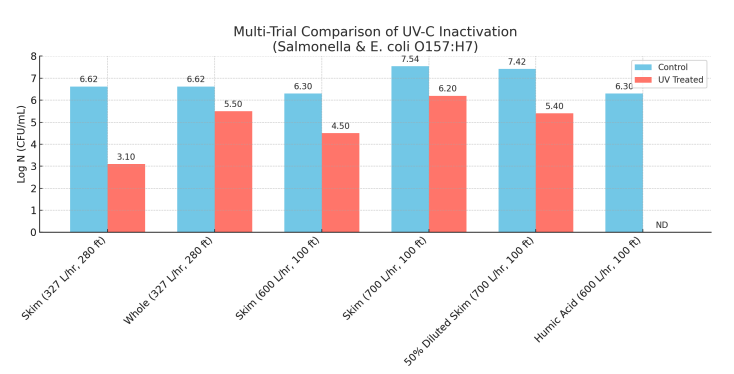

FloUV’s dairy validation program demonstrates consistent microbial inactivation across skim, whole, and diluted milk under industrial flow conditions. Pathogen challenge studies show dose-dependent log reductions of Salmonella, E. coli O157:H7, and other milk-relevant organisms, confirming that engineered flow dynamics enable uniform UV-C fluence delivery even in optically dense matrices. The inactivation curves validate precision dose control as the governing parameter, enabling ≥5-log reduction targets to be achieved without excessive exposure that would compromise milk quality.

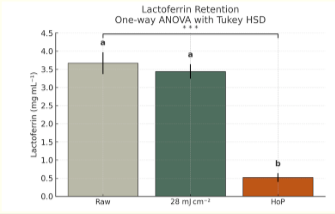

FloUV validation studies demonstrate that precision UV-C processing preserves lactoferrin activity in milk at levels comparable to raw samples, even while achieving microbial safety targets. In contrast to thermal pasteurization, which significantly reduces lactoferrin concentration and functionality, FloUV’s controlled fluence delivery avoids protein denaturation and structural degradation. The results confirm that microbial inactivation and bioactive preservation are not mutually exclusive when UV-C dose is accurately engineered for optically dense milk systems.

Multi-Trial Comparison of UV-C Inactivation

(Salmonela and E Coli O157:H7)

Lactoferrin Retention Activity (Raw vs UV-C Treated vs Heat Pasteurization (HoP)

Better than thermal Pasteurization

Thermal pasteurization achieves microbial safety by applying heat, but at the cost of protein denaturation, enzyme inactivation, flavor alteration, and higher energy demand. FloUV delivers equivalent microbial protection through precision UV-C dosing—without heat—preserving heat-sensitive bioactives such as lactoferrin, IgA, lysozyme, and bile-salt-stimulated lipase. Validation studies show that while heat treatment significantly reduces functional protein activity, FloUV maintains biochemical integrity and sensory quality, enabling dairy processors to meet safety requirements without compromising nutritional or functional performance.

Empowering dairy innovation with FloUV

A purpose-built platform for advanced dairy processing.

FloUV enables processors to unlock new value-added dairy applications—from native whey protein concentrates and bioactive recovery (lactoferrin, IgA) to raw-like yet safe cheese production, raw milk quality enhancement, UHT replacement pathways, and hygienic cheese-brine pasteurization. By combining precision UV-C fluence control with engineered flow dynamics, FloUV supports microbial safety without thermal damage, preserving functionality, flavor, and processing performance. Our modular systems, validation expertise, and application know-how allow seamless integration into existing dairy operations—helping processors move beyond commodity processing toward differentiated, high-value products.