Beyond Thermal. Beyond HPP.

A smarter way to pasteurize juices.

Thermal processing sacrifices quality. HPP adds cost and batch limits. FloUV offers a continuous, non-thermal alternative—validated microbial safety with fresh-like taste, clean labels, and up to 90% lower energy use.

A new world of juice preservation possibilities

FloUV unlocks non-thermal processing opportunities for fresh, functional, and high-value juices. Our engineered UV-C technology combines advanced fluid dynamics with precision dose delivery to ensure microbial safety while preserving natural taste, color, and bioactivity.

We call this TRUE NON-THERMAL PASTEURIZATION

Superior juice quality

The FloUV technology is rooted in fundamental photochemistry and fluid dynamics, applying precisely controlled UV-C energy to inactivate microorganisms without heat or pressure. By combining engineered hydrodynamic mixing with validated dose delivery, FloUV preserves the natural taste, color, aroma, and bioactive compounds of juices—producing products that remain as close to raw and fresh as scientifically possible, while meeting regulatory safety standards.

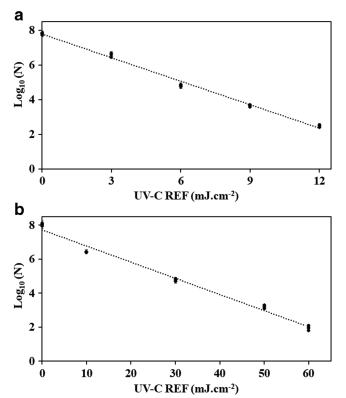

UV-C REF response curves of microbes. a E. coli ATCC 700728.

b B. cereus ATCC 14579 spores

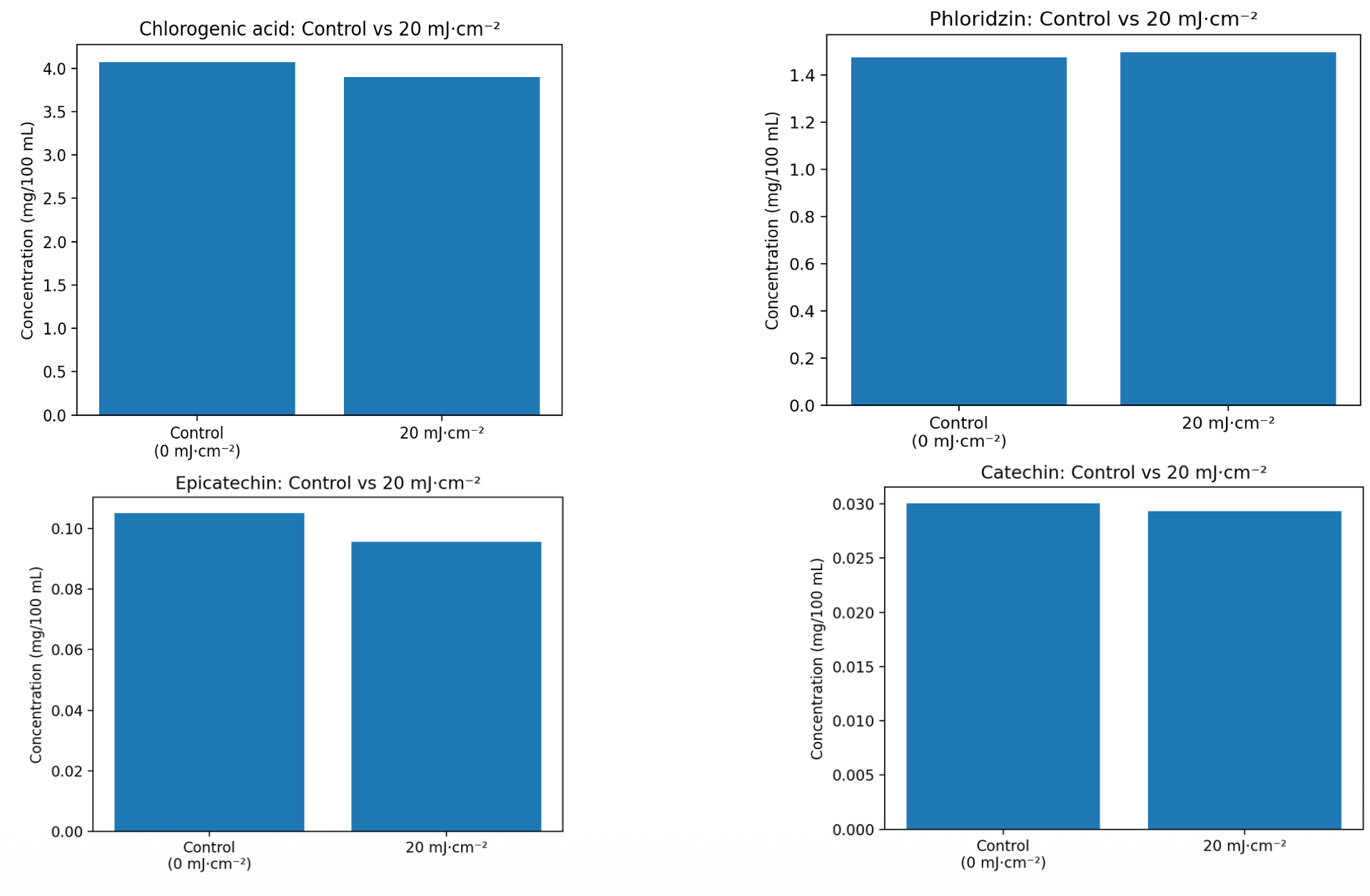

Bioactives Preservation in Fresh Apple Cider

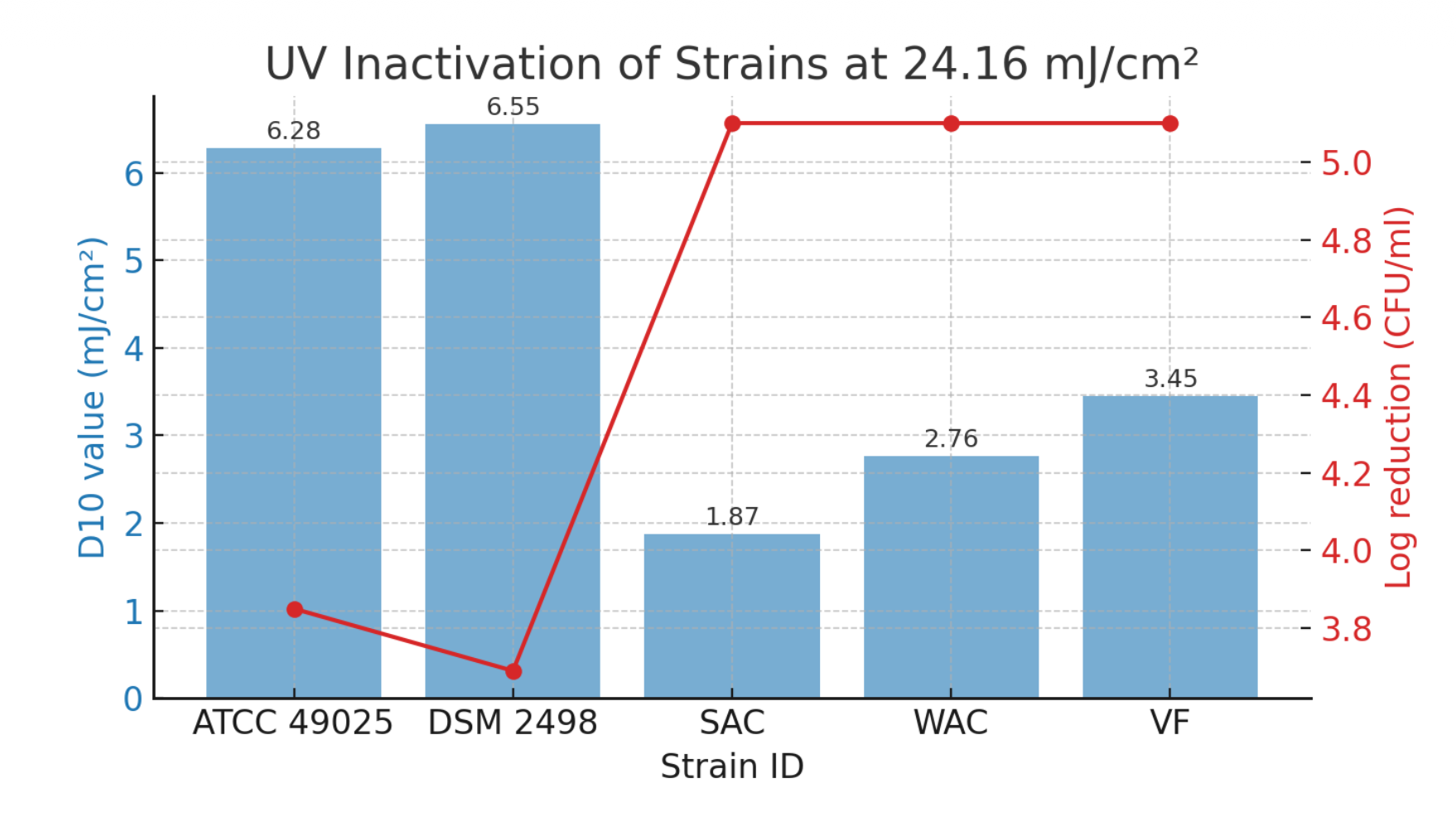

Alicyclobacillus acidoterrestris Spores Inactivation in Fresh Apple Cider

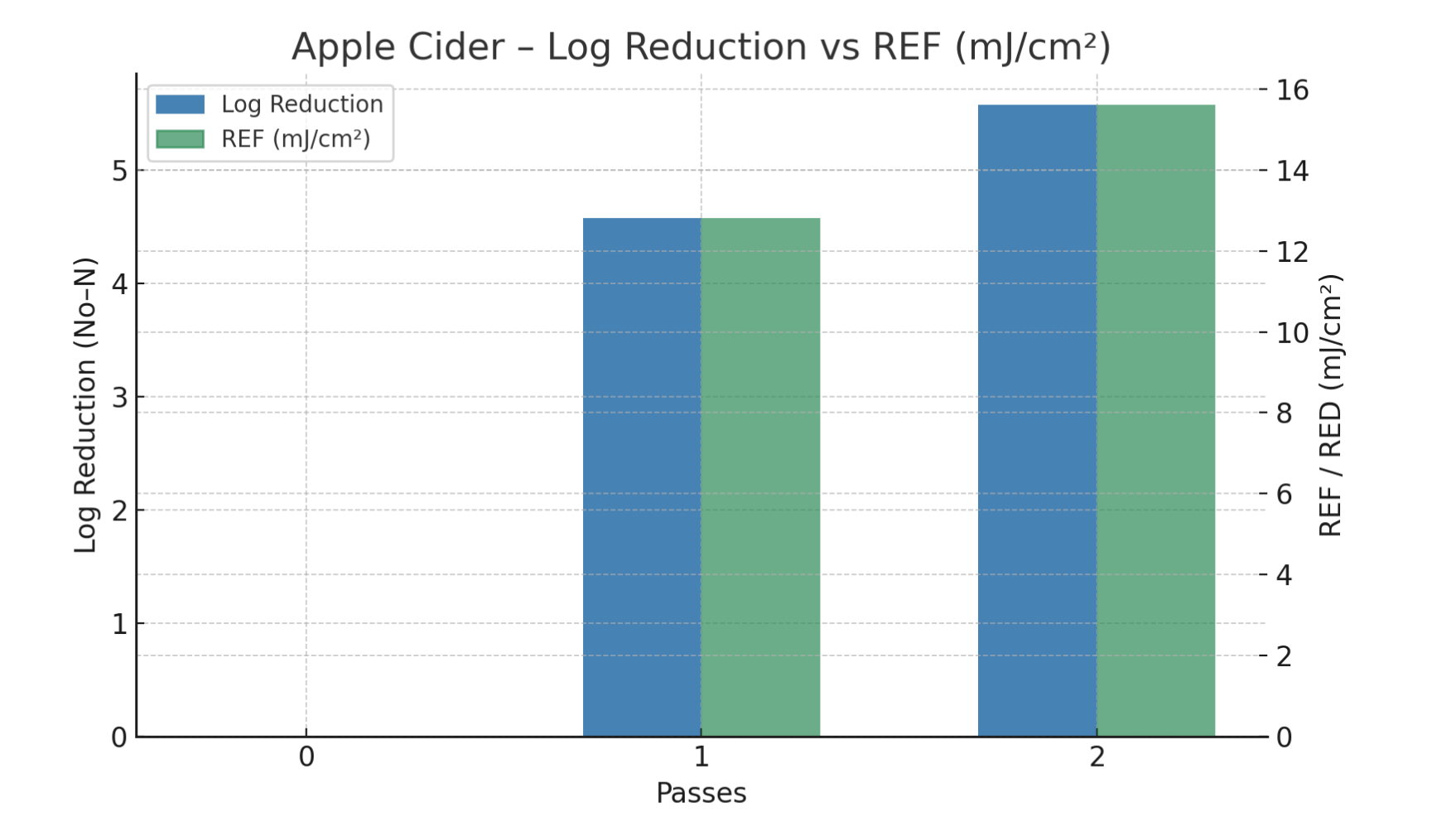

E.Coli O 157:H7 Inactivation in Fresh Apple Cider

Validated microbial reduction with preservation of juice bioactives

FloUV delivers pasteurization-equivalent microbial safety in juices through a non-thermal, UV-C–based process engineered for both clear and turbid matrices. Using validated dose delivery and hydrodynamic mixing, the system achieves ≥5-log reduction of key juice pathogens, including E. coli O157:H7 and Salmonella spp., in alignment with FDA Juice HACCP requirements.

For low-acid and neutral juice applications, FloUV’s validation framework also addresses spore-forming organisms such as Clostridium botulinum through defined dose equivalence targets, ensuring microbial control consistent with pasteurization safety objectives—without reliance on heat or pressure.

Unlike thermal processing, FloUV preserves heat-sensitive bioactive compounds such as vitamins, polyphenols, pigments, and volatile aroma components. Validation studies in apple juice, and simulated results for watermelon juice using the same methodology, demonstrate that high-level microbial inactivation can be achieved while maintaining fresh color, flavor, and nutritional integrity.

The result is juice that remains as close to raw as scientifically possible, while meeting regulatory safety expectations for commercial juice processing.

Built to Replace Heat and Pressure

No batches. No pressure. No compromises.

FloUV runs continuously, in-line, unlike batch-based high-pressure systems that demand heavy CAPEX, long cycle times, and packaging constraints. You get higher throughput, simpler operations, and lower OPEX—without pressure vessels or bottlenecks.

No heat. No burn. No waste.

FloUV replaces energy-intensive thermal pasteurization with precision UV-C, preserving flavor, color, and bioactives while using up to 70% less energy. No fouling, no overheating, and no quality loss—just clean, efficient juice preservation.

Bringing next-generation juice processing to life

From pilot trials to full-scale deployment, FloUV partners with juice processors to deliver validated, non-thermal solutions for even the most challenging juice streams—combining scientific rigor, engineering depth, and real-world application expertise.

Work with our experts to design, validate, and scale your juice application